Achieving the same quality

as aluminum die casting without molding

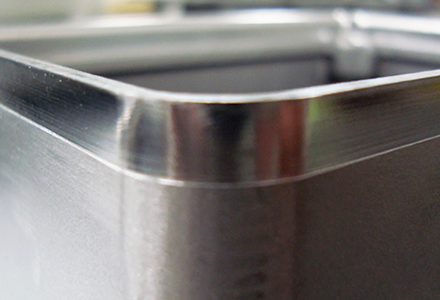

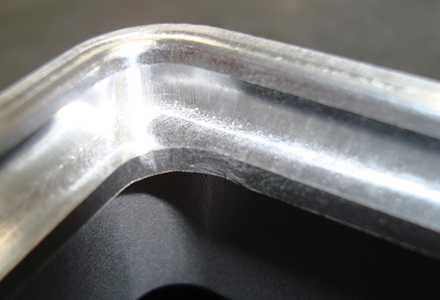

Kyoei Design gypsum casting uses vacuum casting for molding to manufacture prototypes and small quantities of aluminum and zinc alloys that are similar to die casting. This method is unique to us as a pioneer in vacuum casting.

Completed castings are measured and checked by a three-dimensional measuring instrument. Quality and dimensional accuracy are guaranteed.

In addition, this gypsum casting method can be applied to simplified molding of plastics.

Die cast gypsum is used in a wide range of fields,

not just industrial applications and home appliances

Low-defect cast products

In the case that gypsum cast is not to standard, the gypsum mold can be modified and the casting method can be changed easily.

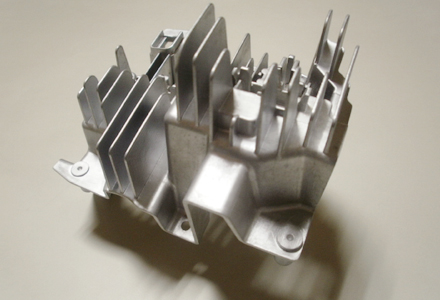

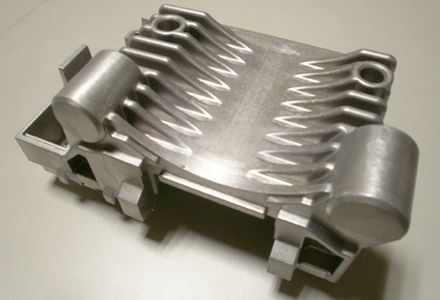

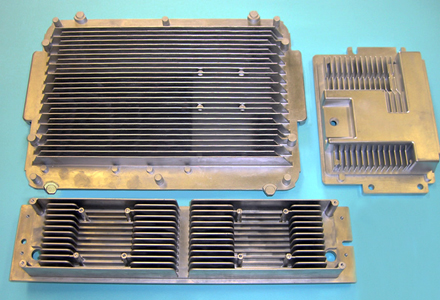

Example of gypsum casting of

high heat radiation alloy DMS series

Heat sink

Size: 150×130×100

Heat sink

Size: φ50×60

Heat sink

Size: φ500×95

Frame of the LED lighting

Size: 300×120×150

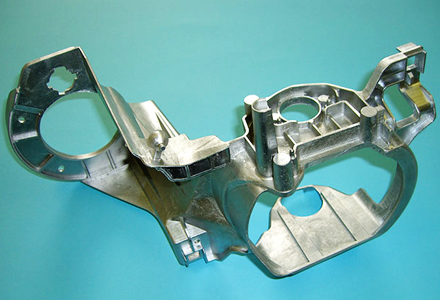

Casting of gypsum for automotive,

industrial and ornamental applications

Automotive reflectors

Size: 400×250×250

Automotive key cylinder

Size: 150×100×80

Heat sink fin

Motorcycle engine joint parts

Size: 80×70×50

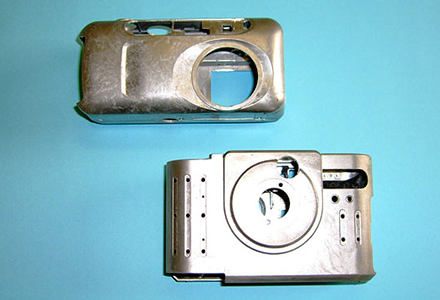

Digital camera

Propeller

Cast gypsum in the shape of roses

Size: φ200×200

Dragonfly: Cast gypsum

Platform: Vacuum casting

Inquiries about gypsum cast products

As a master model for gypsum casting, we will also process plastic products.

If you can supply specifications in the form of drawings etc, Kyoei Design can provide a quotation with the optimal materials and machining method.